THERMAL COVER

Softbox

Thermally-insulated covers is another part of the Softbox jigsaw that helps guard temperature-sensitive products against every conceivable eventuality in the transportation process. Apart from providing the protection, you might expect from damage, dust, rain, moisture, and contamination, our thermal covers slow down temperature exchange. They guard against short spikes that can threaten temperature integrity and product efficacy, often prevalent in loading and off-loading, cross-docking and adverse warehouse conditions.

SilverSkin™ PB500

SilverSkin™ PB550

SilverSkin™ PH300

Key Features

• Qualified performance

• Protects during breaks in the cold chain

• Reduces temperature exchange

• Highly reflective properties

• Protects against freezing

• Water resistant

• Light weight

• Quick and easy to fit

• Protects against contamination

• Tamper-evident

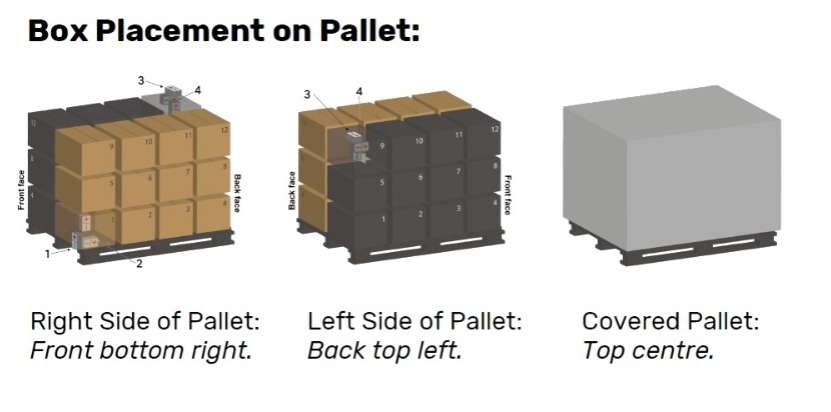

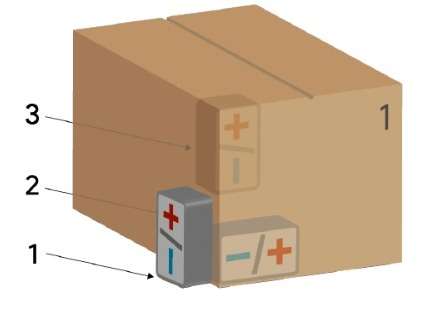

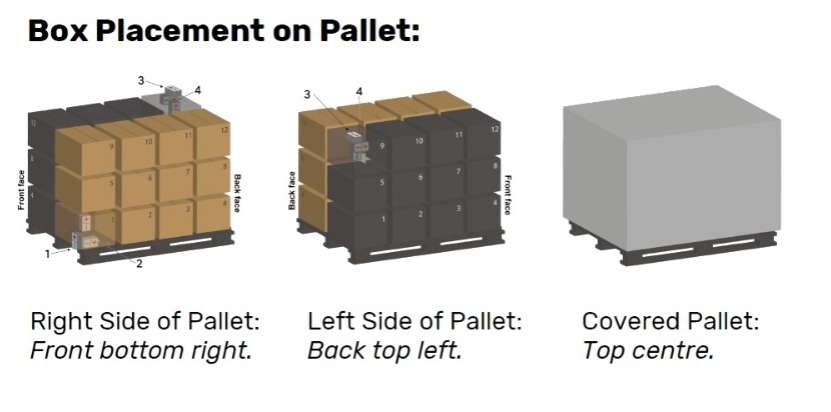

Box Location in the Conditioning Chamber:

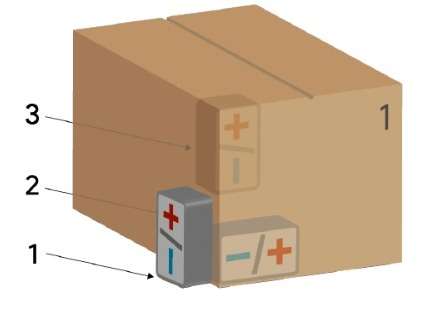

Log Tag Placement in Box:

Test Box 1 Recorder Location:

- Outside Box (monitor, outside corner edge)

2.Inside Box, Product (probe, inside corner)

3.Inside Box, Air (monitor, ambient inside box)

Test Box 2 Recorder Location:

- Outside Box (monitor, outside corner edge)

2.Inside Box, Product (probe, inside corner)

3.Inside Box, Air (monitor, ambient inside box)

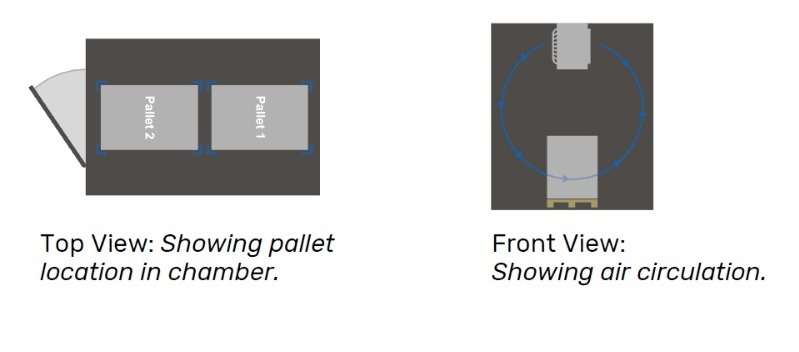

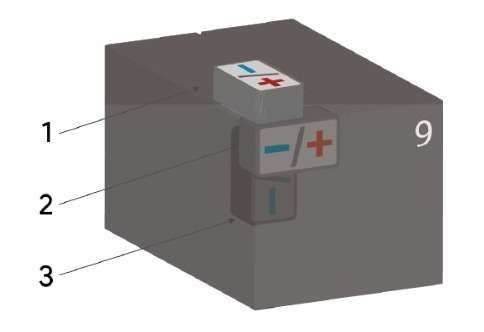

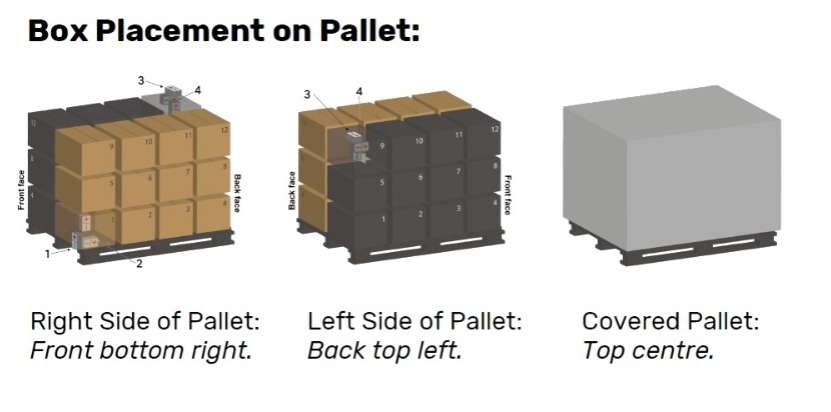

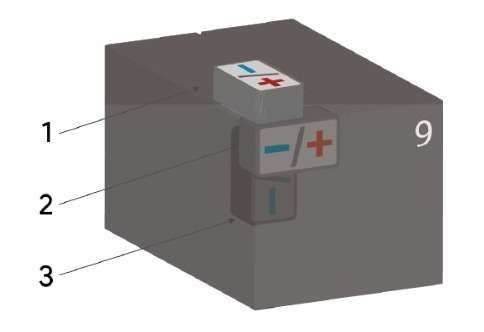

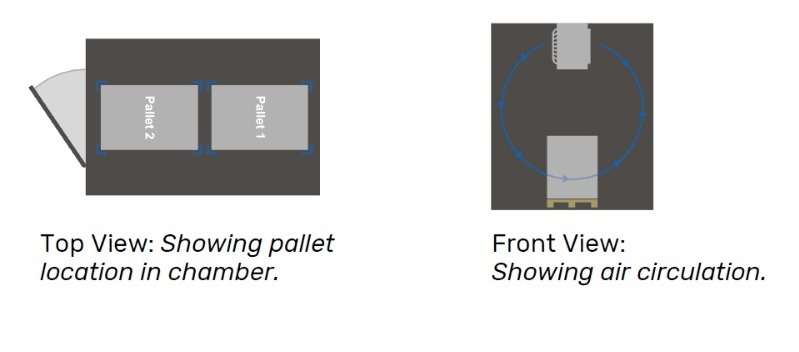

Pallet Location in Chamber:

Pallet 1 is loaded into the chamber before Pallet 2. The front of the pallet faces towards the door to ensure Log Tag positions on each pallet are true to each other.

Softbox

Temperature control packing sysytems

SILVERPODS

SilverSkin™ PB500

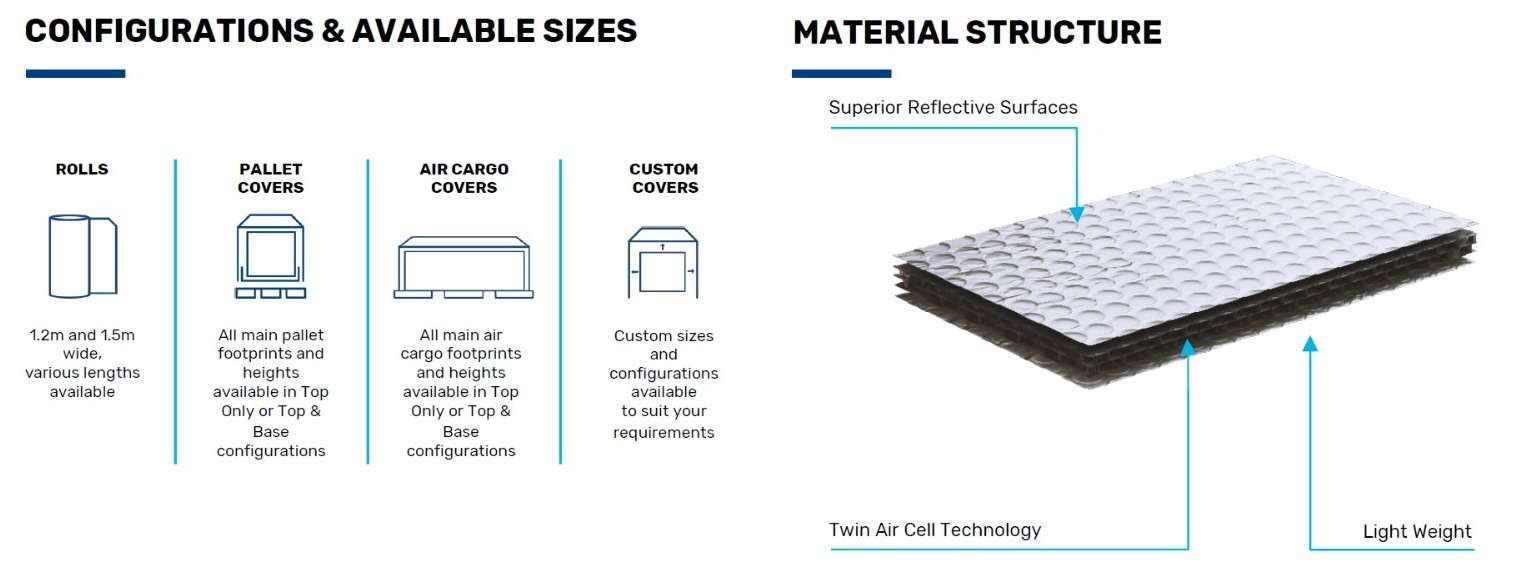

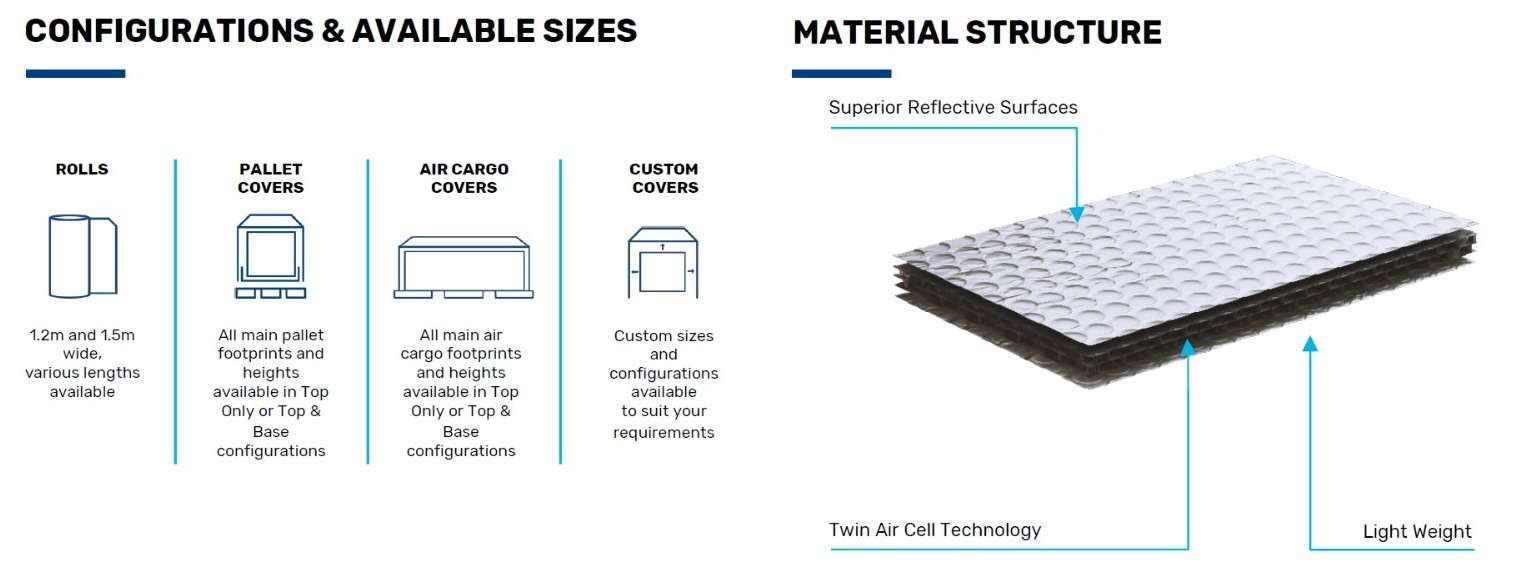

SilverSkinTM PB500 is a durable, twin air cell layer insulation material with dual highly reflective surfaces.

Manufactured using air cell technology, PB500 delays all three types of heat transfer, providing enhanced thermal protection against radiation, convection and conduction. This form stable material provides protection to temperature sensitive freight against spikes in temperature, radiated heat and direct sunlight which can often be encountered during breaks in the cold chain.

Softbox® SilverSkin™

Global Test Program

Softbox® SilverSkinTM thermal performance reports are intended to assist Quality Assurance and logistics professionals in making appropriate decisions on which type of SilverSkinTM thermal cover best meets the needs of their supply chain risk profiles.

Test Method

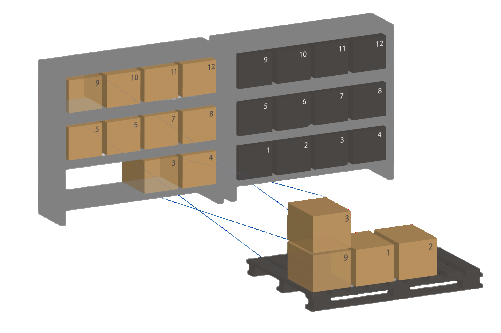

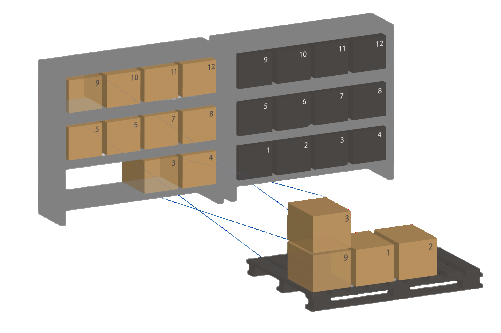

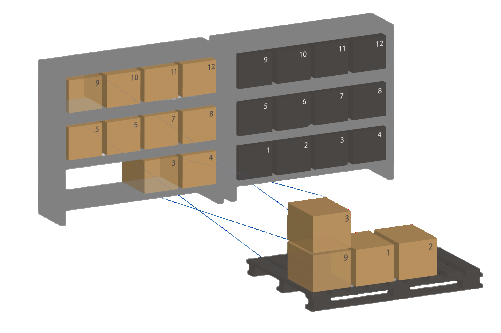

• Pallet Size: Full sized Euro pallets are used 1.2m x 0.8m x 0.15m.

• Test Mass: Pallets contain a mass of 20% – cardboard boxes containing 14 x 500ml (±30ml) bottles of water. Box dimensions 285x385x310mm = 34.01ltr or 34Kg (100% mass).

• Product Conditioning: Test mass is conditioned in the Conditioning Chamber at the required temperature i.e. CRT (control room temperature) +20°C (±3°C), for at least 24 hours before the test. Test mass temperature is visually checked using the LogTag Tred30-7 monitor to make sure the mass is conditioned and ready

to use.

• Pallet Loading: When loading the test Euro pallet, boxes from the same tier of shelf for the LogTag monitors, this will ensure the ‘product’ start temperatures align and are comparable. The pallet is

then completed using the remaining boxes on the two shelves.

Note: a difference of ±1°C may be seen from the lower tier to the top tier.

• Temperature Monitors: Calibrated LogTag Trix-8 and Tred30-7 (World Health Organisation approved) thermocouples are positioned

on the pallet corners to capture data for a ‘worst case scenario’. Three thermocouples per box, two Trix-8 monitors capture ‘air’ data for outside box, under cover and inside box, one Tred30-7 probe is used to capture the ‘product’ temperature inside the box.

Two monitored boxes per pallet are used, with additional Trix-8 monitor placed onto the pallet, outside of the cover to capture the ambient temperature.

Note: The pallets extremity corners to capture temperature data representing a ‘worst case scenario’, to further support this the LogTags must be placed as near to the external corner as possible.

Direct Sunlight Testing: Outdoor trials are carried out in Pune, India between 11.00 and 15.00 to capture hottest part of the day, if weather conditions allow, direct sunlight tests will also be conducted in

the U.K. and in the U.S.A. Chamber Testing: Hot, cold and profile chamber testing is carried out at the Softbox®SilverSkin™Technical Centre in the UK.

ImportantNote: This test summary is designed to provide an ‘indication’ of performance. It should be noted that many factors affect thermal performance including type of freight, mass, packaging, positioning

etc. and that potential users should carry out internal testing to measure performance with product which represents their own. This performance data designed to help support a risk-based approach to GDP.

Key Features

• Qualified performance

• Protects during breaks in the cold chain

• Reduces temperature exchange

• Reflective properties

• Protects against freezing

• Water resistant

• Light weight

• Quick and easy to fit

• Protects against contamination

• Tamper-evident

Box Location in the Conditioning Chamber:

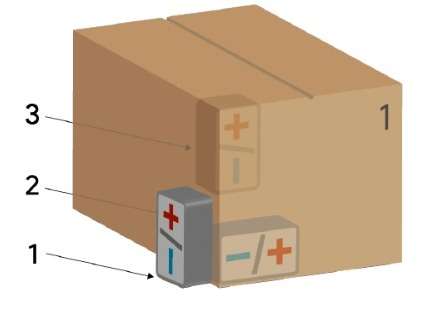

Log Tag Placement in Box:

Test Box 1 Recorder Location:

- Outside Box (monitor, outside corner edge)

2.Inside Box, Product (probe, inside corner)

3.Inside Box, Air (monitor, ambient inside box)

Test Box 2 Recorder Location:

- Outside Box (monitor, outside corner edge)

2.Inside Box, Product (probe, inside corner)

3.Inside Box, Air (monitor, ambient inside box)

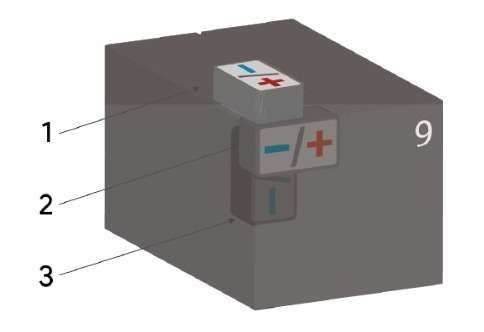

Pallet Location in Chamber:

Pallet 1 is loaded into the chamber before Pallet 2. The front of the pallet faces towards the door to ensure LogTag positions on each pallet are true to each other.

Softbox

Temperature control packing sysytems

SILVERPODS

SilverSkin™ PB550

SilverSkinTM PB550 is a durable, entry level single air cell layer insulation material with dual reflective

surfaces. Manufactured using air cell technology, PB550 delays all three types of heat transfer, providing enhanced thermal protection against radiation, convection and conduction. This form stable material provides protection to

temperature sensitive freight against spikes in temperature, radiated heat and direct sunlight which can often be encountered during breaks in the cold chain.

Softbox® SilverSkin™

Global Test Program

Key Features

• Qualified performance

• Protects during breaks in the cold chain

• Reduces temperature exchange

• Highly reflective properties

• Protects against freezing

• Water resistant

• Light weight

• Quick and easy to fit

• Protects against contamination

• Tamper-evident

Box Location in the Conditioning Chamber:

Inside Conditioning Chamber:

Two shelves, containing a total of 24 boxes are used to

complete one Euro sized test pallet.

Log Tag Placement in Box:

Test Box 1 Recorder Location:

- Outside Box (monitor, outside corner edge)

2.Inside Box, Product (probe, inside corner)

3.Inside Box, Air (monitor, ambient inside box)

Test Box 2 Recorder Location:

- Outside Box (monitor, outside corner edge)

2.Inside Box, Product (probe, inside corner)

3.Inside Box, Air (monitor, ambient inside box)

Pallet Location in Chamber:

Pallet 1 is loaded into the chamber before Pallet 2. The front of the pallet faces towards the door to ensure LogTag positions on each pallet are true to each other.

Softbox

Temperature control packing sysytems

SILVERPODS

SilverSkin™ PH300

SilverSkinTM PH300 is a durable, single non-woven layer material with highly reflective surfaces.

Manufactured as a specialist single skin material, PH300 delays heat transfer by providing enhanced

thermal protection against radiation and convection. This form stable material provides protection to

temperature sensitive freight against spikes in temperature, radiated heat and direct sunlight

which can often be encountered during breaks in the cold chain.

Softbox® SilverSkin™

Global Test Program

Softbox® SilverSkinTM thermal performance reports are intended to assist Quality Assurance and logistics professionals in making appropriate decisions on which type of SilverSkinTM thermal cover best meets the needs of their supply chain risk profiles.

Test Method

• Pallet Size: Full sized Euro pallets are used 1.2m x 0.8m x 0.15m.

• Test Mass: Pallets contain a mass of 20% – cardboard boxes containing 14 x 500ml (±30ml) bottles of water. Box dimensions 285x385x310mm = 34.01ltr or 34Kg (100% mass).

• Product Conditioning: Test mass is conditioned in the Conditioning Chamber at the required temperature i.e. CRT (control room temperature) +20°C (±3°C), for at least 24 hours before the test. Test mass temperature is visually checked using the LogTag Tred30-7 monitor to make sure the mass is conditioned and ready

to use.

• Pallet Loading: When loading the test Euro pallet, boxes from the same tier of shelf for the LogTag monitors, this will ensure the ‘product’ start temperatures align and are comparable. The pallet is

then completed using the remaining boxes on the two shelves.

Note: a difference of ±1°C may be seen from the lower tier to the top tier.

• Temperature Monitors: Calibrated LogTag Trix-8 and Tred30-7 (World Health Organisation approved) thermocouples are positioned on the pallet corners to capture data for a ‘worst case scenario’. Three thermocouples per box, two Trix-8 monitors capture ‘air’ data for outside box, under cover and inside box, one Tred30-7 probe is used to capture the ‘product’ temperature inside the box.

Two monitored boxes per pallet are used, with additional Trix-8 monitor placed onto the pallet, outside of the cover to capture the ambient temperature.

Note: The pallets extremity corners to capture temperature data representing a ‘worst case scenario’, to further support this the LogTags must be placed as near to the external corner as possible.

Direct Sunlight Testing: Outdoor trials are carried out in Pune, India between 11.00 and 15.00 to capture hottest part of the day, if weather conditions allow, direct sunlight tests will also be conducted in

the U.K. and in the U.S.A. Chamber Testing: Hot, cold and profile chamber testing is carried out at the Softbox®SilverSkin™Technical Centre in the UK.

ImportantNote: This test summary is designed to provide an ‘indication’ of performance. It should be noted that many factors affect thermal performance including type of freight, mass, packaging, positioning

etc. and that potential users should carry out internal testing to measure performance with product which represents their own. This performance data designed to help support a risk-based approach to

GDP.